In recent years, people and professionals worldwide have become increasingly conscious of their impact on the environment. Sustainable living innovations are constantly emerging, with one of the latest breakthroughs being structural thermal break materials. This innovative material is designed to reduce the amount of heat that is lost through a building’s structure, making it more energy efficient.

Structural thermal break material is a crucial component for building and construction professionals and structural engineers. Across the industry, the material is being specified for use in new steel structures and projects as cities and firms across the world strive to meet greener energy standards.

Are you ready to make your next structure your most sustainable yet? In this informative guide, we’ll break down the basics of thermal bridging, explore how structural thermal break improves sustainable designs, and provide information on where to obtain this remarkable material.

What is Thermal Bridging?

Thermal bridging occurs when a material of higher thermal conductivity acts as a “bridge” for heat transfer. Heat will always travel via the path of least resistance to the colder side. Steel is a highly conductive material for heat. While it’s a great material for building, it can lead to energy inefficiencies if not designed properly.

This phenomenon is a common concern for structural engineers and a crucial factor for engineers and architects to consider in their future designs. Thermal bridging not only results in energy loss but can also create uncomfortable environments for those occupying the building. Additionally, improper insulation can cause condensation to collect around areas where heat transfers.

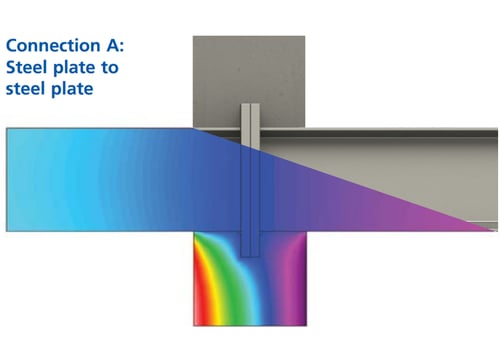

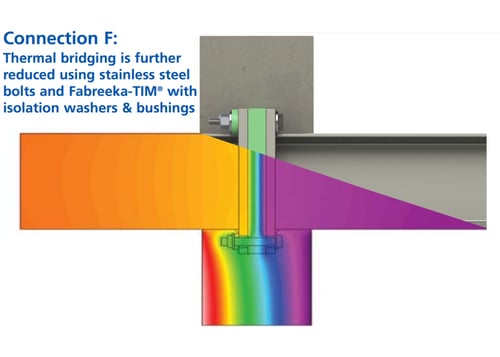

So, where does structural thermal break fit into all this? Let’s take a closer look at a standard thermal break connection compared to a standard steel connection. 👇

How Does Thermal Break Material Work?

A structural thermal break is a component used in building construction to prevent heat loss and gain through structural connections. This is achieved by introducing a low thermal conductivity material between the two sides of the connection, which effectively breaks the thermal bridge and reduces energy transfer.

This not only improves the energy efficiency of the building but also enhances its overall structural performance. By mitigating thermal bridging, structural thermal breaks can help reduce the risk of condensation and mold growth, resulting in a more comfortable and healthier indoor environment.

In the first image, there is no thermal break material present. The steel beams are connected, likely through steel bolts, without a thermal barrier. The heat from the warmer side of the beam easily passes through to the other side via the connection. This connection is structurally sound, but it is also energy-inefficient.

In the second image, the thermal transfer is clearly interrupted by the thermal barrier or thermal break. Both hot and cold sides are separated by thermal break material, greatly reducing the amount of heat that transfers to the other side. If you look closer, you can see the material is also integrated into the bolt connections as well. Since heat naturally follows via the path of least resistance, it would attempt to transfer via the bolt connections if no thermal break material were present.

READ NEXT: [What is the Best Thermal Break Material?]

Sustainable Design Examples

There are plenty of real-world sustainable design examples that utilize structural thermal break material. As more structural engineers and architects seek eco-friendly options for their projects, more and more professionals are turning to thermal break in the field. Below, we explore some great examples of how this material is incorporated.

Structural Steel Framing

Structural Steel Framing

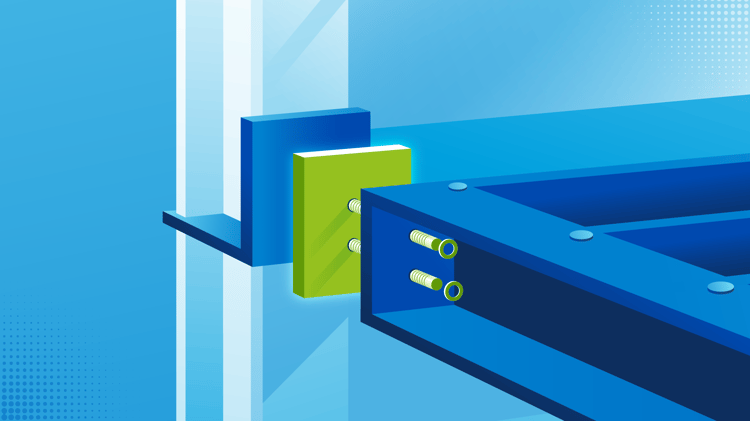

In the image to the right, you can clearly observe Fabreeka's own structural thermal break material, easily recognizable by its iconic green color, It is installed around the bolt connections and positioned between the steel plates.

This amazing application was done for an observatory and botanical garden. Structural thermal breaks were strategically installed at critical connection points within the structural steel frame. These points were identified as the most vulnerable to heat loss, primarily due to their proximity to outdoor conditions.

External Additions and Connections

External Additions and Connections

Here is another example of our material’s application where the material is installed between two steel-to-steel plate connections. This specific section of the steel frame connects to an additional structural component, which is more likely to contribute to heat loss or heat transfer, depending on the climate conditions.

Whether applied in entire structural frames, steel structures, or similar additions, Fabreeka-TIM structural thermal break prove effective in a wide range of steel connections and applications.

Fabreeka-TIM® Structural Thermal Break.png?width=265&height=265&name=TIM_Transparent%20(1).png)

Now that you've witnessed how this remarkable material performs in real-world applications, let's talk a bit more about why Fabreeka-TIM is the best choice for structural engineers and architects. Available in various thicknesses and custom cut to suit your specific application, this material sets the industry standard for sustainable living innovations.

Fabreeka-TIM structural thermal break is proven in the field, for industry professionals rely on our thermal break to reduce heat loss, boost energy efficiency, and maintain structural integrity.

While Fabreeka-TIM is exceptionally well-suited for steel structures, we also offer another series of thermal break materials designed for applications with lighter loads but requiring equally impressive results. ⬇

Fabreeka-TIM® RF Series

The "rigid foam" series of our thermal break material has all the same great insulation properties for a variety of other applications. Fabreeka-TIM RF series consists of polyurethane foam, ideal for applications such as column base insulation, cold storage, balcony connections, and more. Available in multiple densities, Fabreeka-TIM RF is a versatile thermal break option.

Moreover, this fantastic foam material is impermeable to water, oil, mildew, brine, and harsh weather environments. Our rigid foam thermal break material is a valuable asset for reducing thermal transfer in non-moment connections while ensuring long-lasting quality and performance.

Conclusion

In conclusion, structural thermal break material represents a groundbreaking sustainable living innovation that is revolutionizing the construction industry. By reducing heat loss and enhancing energy efficiency, this material not only helps create more environmentally friendly buildings but also elevates their overall structural performance.

From preventing thermal bridging to mitigating the risk of condensation and mold growth, structural thermal breaks offer numerous benefits for architects, engineers, and occupants alike. With real-world examples illustrating its effectiveness, it is evident that this material is a game-changer in the realm of sustainable design. If you aspire to make your next project your most sustainable one yet, consider incorporating structural thermal break material into your construction.

To delve deeper into this amazing innovation and explore the finest thermal break materials available, we encourage you to download our in-depth guide. Together, we can work towards creating a greener and more sustainable future for our built environment.

SUBMIT YOUR COMMENT