Discover how Fabreeka Pad and vibration control solutions are crucial in enhancing efficiency and reliability in the oil and gas industry.

How Vibration Affects the Oil and Gas Industry

Although we interact with vibration in everyday life, it can have significant consequences on operations and equipment in oil and gas. The most common are equipment failures, increased maintenance expenses, and reduced productivity. The continuous shaking and movement caused by vibration can lead to fatigue and stress on pipelines, machinery, and other infrastructure, resulting in the formation of cracks, leaks, and other structural issues.

In addition to the physical damage caused by vibration, it can also affect the accuracy of measurements and readings in the industry. Vibration can interfere with sensors and instruments, leading to inaccurate data and potential safety hazards. This can be particularly problematic in tasks such as drilling, where precise measurements are crucial for success and safety.

Vibration Control in Oil and Gas Applications

Vibration control plays a critical role in various oil and gas applications to minimize the negative effects of vibration. By implementing vibration control measures, companies can improve the lifespan and performance of equipment, reduce downtime, and enhance overall operational efficiency.

READ NEXT: [Optimizing Safety: Reducing Vibration in Oil and Gas Transportation]

Fabcel® Pads are used in a wide range of oil and gas applications, including compressors, pumps, turbines, generators, and pipelines. By installing Fabcel pads, companies can effectively reduce the transmission of vibration from equipment to surrounding structures, minimizing the risk of damage, and improving overall performance. This vibration-reducing material is also resistant to oil, water, and other chemicals commonly found in the industry, ensuring long-lasting performance even in harsh environments.

The use of vibration control solutions like Fabcel is crucial for ensuring the safety, reliability, and efficiency of oil and gas operations.

Fabcel: Superior Vibration Control

With a history of over 60 years in the field, Fabcel® nitrile rubber pads have proven to be highly effective in reducing low frequency vibration. Their unique "waffle" shape allows them to support higher loads compared to other pads, while also effectively reducing shock and vibration even in extreme conditions. Let's jump in and discover the various applications of vibration control in the industry. 👇

Gas Pumps and Gas Extraction

Our materials are particularly effective in isolating the high-pressure gas pumps that extract gas from the ground. The high speeds and forces involved in this process can create potential vibration issues. Fabcel® pads effectively stabilize gas trains and extractors of all types, ensuring proper operation and extending the maintenance life of the equipment. Considering the industry's ongoing efforts to expand and improve extraction and export processes, Fabreeka's materials play a crucial role in preventing the high speeds of these operations from negatively impacting pipelines. Our products are designed to protect oil and gas equipment ensuring their longevity and reducing risk.

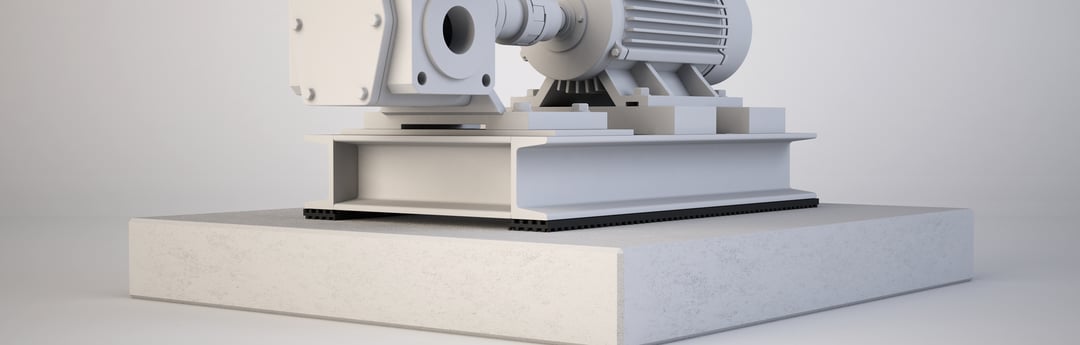

Compressors

Fabreeka® vibration isolation and shock control materials are engineered to meet the high standards of oil and gas compressors. Combined with our whole-system approach to mitigate vibration, our solutions provide exceptional benefits. Fabcel’s exceptional damping capabilities and waffle-cell geometry extend the life of compressors by reducing vibration transmission at critical points. Available in high densities, Fabreeka’s engineers can design our vibration reduction material for any compressor.

Offshore Drilling

Whether used on land or offshore, our materials have been tested and proven to reduce vibration transmission, improving efficiency in oil rigs. We take great care in designing solutions that isolate the drilling rig on the platform, ensuring safety and optimal operation. For offshore rigs, we even offer vibration reduction systems that protect the crew on board. We can also isolate living quarters to safeguard the well-being of workers, ensuring that regular operations do not compromise their safety.

The Fabreeka Pad: Trusted, Tested, and Timeless

Tested, and Timeless

The versatility of Fabreeka Pads makes them the go-to solution for a wide range of applications in the oil and gas industry. These pads have proven to be highly effective in minimizing vibrations and reducing the risk of equipment failure.

The use of Fabreeka Pads in pumps helps improve performance and reliability by reducing the impact of vibrations. By absorbing the vibrations generated by operation, these pads minimize the risk of structural damage and extend the lifespan of the equipment. This not only leads to cost savings in terms of maintenance and repairs but also enhances overall operational efficiency.

Fabreeka Expansion Bearings

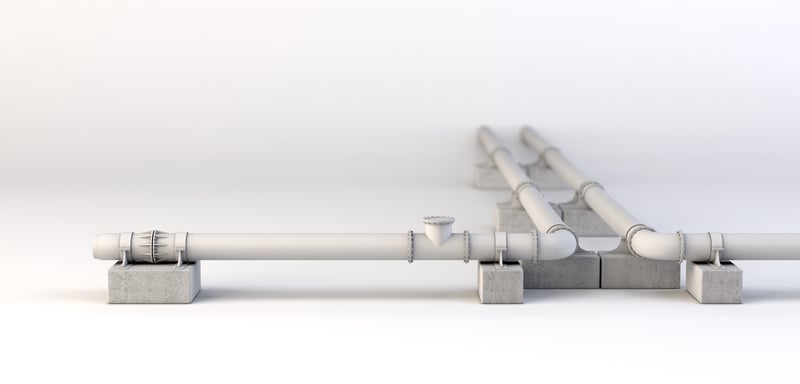

We offer versatile expansion bearings that come equipped with PTFE for effortless sliding and expansion. STX and SBX bearings from Fabreeka are also used in pipe supports where high expansion is needed for piping.

Fabreeka-PTFE

Fabreeka’s engineered materials are excellent solutions for mechanical restraints to control and reduce vibration in piping. The Fabreeka Pad excels in harsh environments where thermal insulation and expansion are necessary. Fabreeka Pad is commonly bonded to pipe clamps and base plates to maintain operation life and reduce the effect of pipe pulsations and vibrations. When used with PTFE, the pad’s thermal capabilities are enhanced, making it a popular choice for pipe supports in the field.

-1.png?width=500&height=240&name=FABREEKA_Category_Energy-01b_RGB-M%20(1)-1.png)

In conclusion, vibration control solutions play a crucial role in enhancing efficiency and reliability in the oil and gas industry. By implementing vibration control measures, companies can improve the lifespan and performance of equipment, reduce downtime, and enhance overall operational efficiency.

Whether it is stabilizing gas pumps, extending the life of compressors, or improving efficiency in offshore drilling, Fabreeka's materials have proven to be highly effective. Engage further to learn more about the various applications of vibration control in the oil and gas industry and discover how Fabreeka's trusted and tested solutions can benefit your operations.

.png?width=250&height=250&name=Slide%20Bearing%20Transparent%20(1).png)

SUBMIT YOUR COMMENT