In an industry reliant on efficiency, repeatability, and reliability, it is crucial that oil and gas equipment incorporates the necessary components to maintain safe and efficient operations. Piping, oil rigs, gas trains, and more are all exposed to significant vibrational forces, which can displace equipment and lead to several other equipment issues.

Furthermore, safety is a top concern for professionals in the oil and gas industry. Equipment failures and damages resulting from vibrational forces not only cause additional maintenance but can put workers at an increased risk as well. Let’s take a closer look how vibration can adversely affect oil and gas equipment.

How Does Vibration Affect Oil and Gas Equipment?

Vibration is everywhere in the world around us, taking on various forms from subtle to extreme. In the context of oil and gas equipment, vibration naturally occurs due to the operation of machinery and equipment. The severity of the vibration and its impact on different equipment pieces can vary.

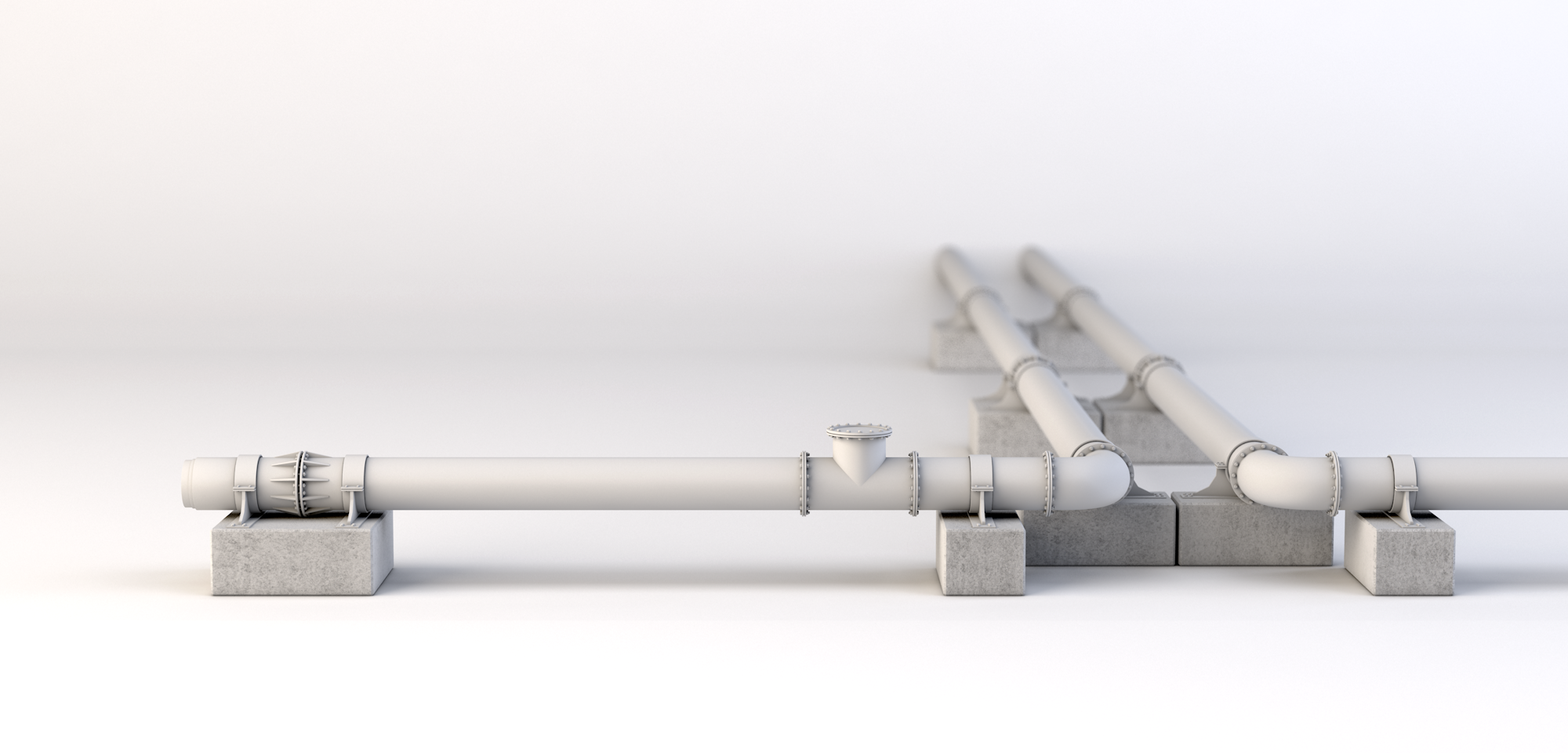

For instance, gas pipelines are subjected to vibrational forces as oil flows through the pipes during the transportation process. The high-speed movement of extracted gas in substantial quantities amplifies the generated vibration. Consequently, these forces cause the pipes to shake, transmitting vibrations throughout the piping and the support structure it rests on.

Gas Trains, Compressors and Drilling Rigs

Much like pipelines, gas extraction equipment such as drilling rigs and gas trains create vibration simply through operation. Oil and gas equipment of such a scale produces continuous vibratory forces that can degrade the machine’s integrity over time. Vibration naturally travels through areas of least resistance, leaving transmission points, such as bolt connections, especially vulnerable.

From these points, vibrations disperse into the surrounding environment. Subtle, low frequency vibrations aren’t usually cause for concern, but excessive vibration caused by intense machine operation creates unsafe working conditions, especially for those on offshore drilling rigs. In these environments, vibration from the rigs can be felt in living quarters and anywhere else throughout its operation.

READ NEXT: [“Four Ways to Achieve Vibration Isolation in Oil and Gas Production”]

When Does Vibration Become a Safety Hazard?

If left unaddressed, excessive vibration can lead to equipment failures and safety hazards down the line. Vibration becomes a safety hazard when there is visible damage or excessive vibrational forces spread to the surrounding environment. We always feel vibration, but if you really feel it, and notice structural or equipment damage, then it’s time to look for a solution.

Moreover, vibration has a significant impact on the productivity and efficiency of both oil and gas equipment and the employees using them. Especially true for offshore oil rigs, excessive vibration leads to uncomfortable and hazardous living conditions for those on board. Such disturbances can lead to physical and mental health problems for employees. In other cases, excessive vibration that leads to equipment failure can really spell trouble for those working nearby.

Vibration Control for Oil and Gas Extraction

Luckily, there are plenty of great solutions that use high-quality, time-tested materials to reduce vibration across different applications in the industry. These solutions enhance safety and efficiency by reducing the transmission of vibrational forces to people, machines, and the environment.

Vibration isolation and shock control has proven effective for the oil and gas industry for decades. As experts in the field, Fabreeka® International delivers on over six decades of industry expertise to develop top-notch vibration control solutions for the oil and gas sector.

Our engineers utilize the best materials to deliver on their industry and vibration control expertise. Discover what Fabreeka’s line of solutions for the oil and gas industry can mean for your operations. 👇

Fabreeka® Expansion Bearings: The Ultimate Solution for Pipe Clamps and Supports

To meet the stringent standards of the oil and gas industry, Fabreeka expansion bearings provide an ideal solution for pipe clamps and supports. Our line of PTFE-equipped expansion bearings allows for effortless sliding and expansion wherever needed.

Equipped with our signature Fabreeka® Pad, the SBX expansion bearings stand as the toughest solution available for pipe clamp and support applications. Fabreeka’s engineered materials serve as excellent solutions for mechanical restraints to control and reduce vibration in piping. When used with PTFE, the pad’s thermal capabilities are enhanced, making it a popular choice for pipe supports in the field.

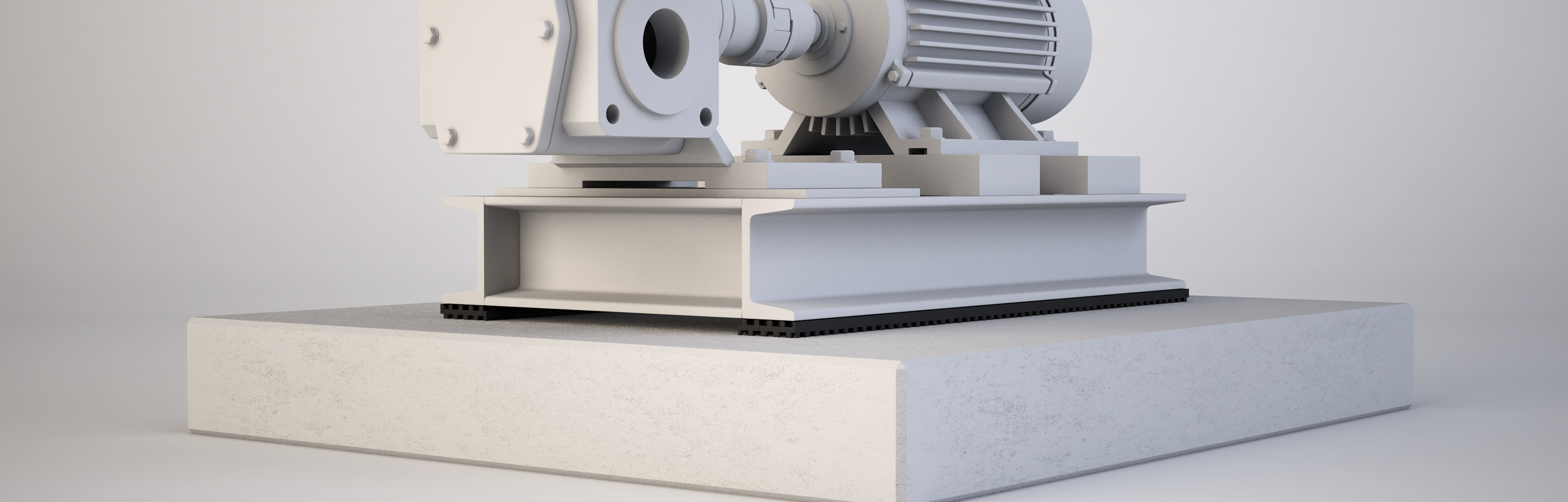

Fabcel®: Durable Low-Frequency Vibration Reduction

Fabcel®: Durable Low-Frequency Vibration Reduction

Effectively serving for over 60 years in the field, Fabcel® nitrile rubber pads efficiently reduce low-frequency vibration. The unique “waffle” shape enables the pad to support heavier loads than other pads while reducing shock and vibration in extreme conditions. Quality and reliability are synonymous with Fabreeka materials, and Fabcel® is no exception.

Fabcel’s resilience and tested durability make it the premier vibration control material. Whether on land or offshores, our materials are proven to reduce vibration transmission and improve efficiency in oil rigs. We design our solutions to isolate the drilling rig on the platform to ensure safety and proper operation. For offshore rigs, we can even design custom vibration reduction systems to protect those on board. We can isolate living quarters to ensure regular operations do not jeopardize the safety of your workers.

Fabreeka® Pad: The Superior Material for Shock Control

The original cotton duck, elastomeric pad, Fabreeka® Pad is ideally suited to withstand the conditions commonly encountered in the oil and gas industry. Impermeable to oils, steam, water, mildew, and brine, our signature shock control solution keeps equipment and operation for years.

The pad’s high damping rate of 14% and load accommodation of up to 10,000 psi make it an ideal material for the most challenging applications the oil and gas industry has to offer. Moreover, the pad meets military spec MIL-C-882, attesting to its reliability.

The Fabreeka Pad excels in harsh environments where thermal insulation and expansion are necessary. It is commonly bonded to pipe clamps and base plates to prolong operational life and reduce the impact of pipe pulsations and vibrations.

Whether you are working offshore or on land, Fabreeka has a solution for every vibration problem. For more information on the oil and gas industry, and Fabreeka’s work in the field, consider subscribing to our blog to receive industry-leading insights like this directly to your inbox. 📬

SUBMIT YOUR COMMENT